Clamp Droplet Titanium W/Latch

Description

Clip "Droplet" titanium with latch

Clamp "Droplet" titanium with a latch 10.05M is a variation of the model 10.05 ., which has a special latch on the movable cheek of the clamp. This allows you to reinstall the rope without unfastening the clamp.

The popular droplet clamp is designed to provide safety and fall protection for a climber at a height. It can also be used when climbing vertical or inclined rope "handrails" and for self-insurance of an athlete-climber, if he trains alone. Another use case is in polypass systems.

The clamp is used on ropes with a diameter of 8 to 12 mm.

Without load, the ascender moves easily both up and down the rope.

Without the help of hands, it accompanies the climber when moving up.

In the event of a breakdown, as well as with a sharp downward load, the clamp automatically grabs the rope and fixes on it.

The clip holds equally well on both dry and icy or dirty ropes.

"Droplet" is great for positioning - it does not slide off the rope under its own weight.

The "cams" of the clamp have a special milled recess (fillet) at the ends. This prevents cutting of the sheath and biting of the rope under heavy loads. The ascender complies with the UIAA standard (applying a load of 400 kg 5 times in a row without deforming the ascender and damaging the rope).

The case of this model is made of high-strength titanium with a decorative signature pattern "Frost". The axis of the "cam" is also titanium. The "cam" and "heel" of the clamp itself are made of high-strength duralumin V-95. They are not cast from metal, as many other manufacturers do, but are made by machining (milling), which practically eliminates the presence of defects in the metal. Additionally, the "cams" have a wear-resistant coating - chemical nickel.

The clamp complies with the European standard EN 567.

Retail price

This Product is Hard to Find.

We don’t know where you can buy this item online in the US. We’ll continue to check all the major retailers and will update this page as soon as we find one.

If you know where to find this online in the US, let us know, and we’ll add the link.

| Weight (g) | 133 g |

Ascender Type  Ascender Type

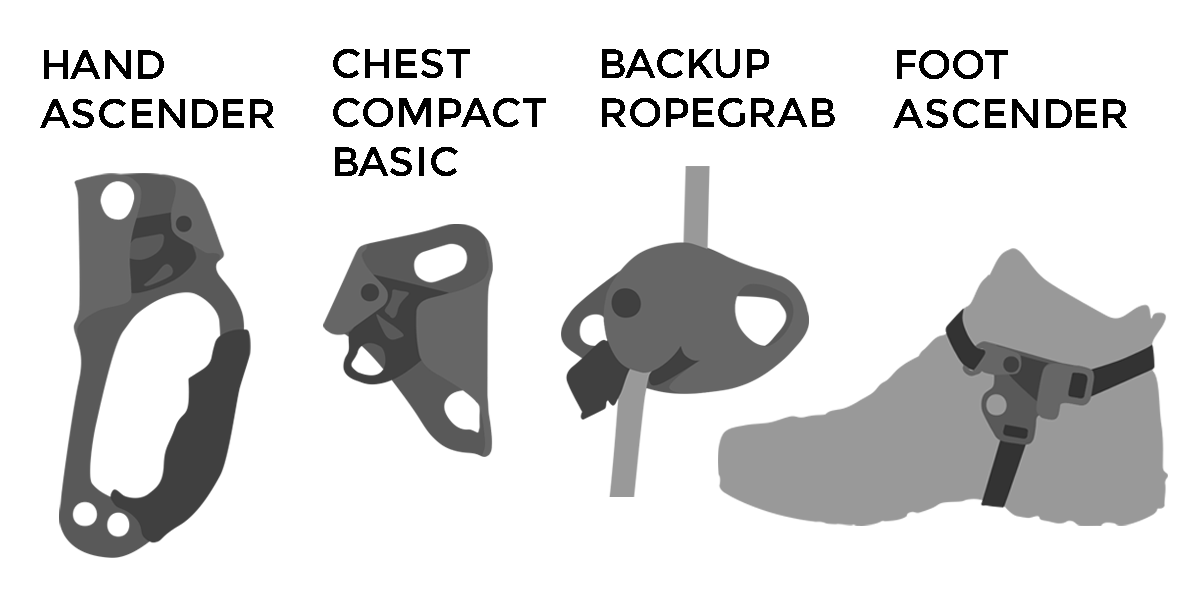

HandHand ascenders are used to manually ascend rope by pulling down with hands. They always have handles and are typically made in left and right hand versions. Chest/Compact/BasicChest, Compact and Basic ascenders are often used in conjunction with other rigging or devices for ascending rope or progress capture. Their shape is made to be pulled down on and they have lower holes for attachment, though they aren’t as comfortable to use as hand ascenders. The upper holes also allow them to be used as a trailing backup. Backup/Rope GrabBackup or Rope Grab ascenders are used as emergency backups and efficiency devices in hauling situations. They are usually trailed behind a climber via a sling when ascending a fixed line, or to give mechanical hold on a rope when pulling on a weighted line. FootFoot ascenders allow direct attachment of the foot to a rope and are most often used in arboriculture and work at height situations where the only thing to climb is a rope. They typically do not have holes for attachment of carabiners and do not function as safety backups. |

Backup / Rope Grab / Capture Pulley |

Tooth Type  Tooth TypeToothedThe teeth on toothed ascenders are usually conical and sharp. They are designed to physically bite into the sheath of the rope. Toothed ascenders are the most common for devices made to climb rope.

RidgedRidged tooth ascenders clamp on the rope with flat, jagged teeth that are the width of the device. The teeth do not bite into the rope sheath but rather clamp it with the force of the triangular shape of the teeth. Ridged teeth are usually seen on backup ascenders but do also appear on foot, chest and pulley capture devices.

SmoothVery few toothless ascenders exist but some manufacturers tout toothless as a benefit of reducing wear on ropes. This style is mostly found on rope clamp/hauling devices.  |

Smooth / None |

Bottom Holes  Bottom HolesBottom HolesManufacturers provide holes for attaching carabiners and equipment to the bottom of ascenders. Some of these are made to accept one or more carabiners, while others are designed to accept one carabiner and a quick link (or maillon) for semi-permanently attaching a loop or ladder. Usually only ascenders made to operate attached to or above a climber have lower attachment holes. This option only applies to devices with both Upper and Lower holes. | Not applicable for this ascender type |

Handedness  HandednessHandsHand ascenders are made with handles designed to be held and operated by the left or the right hand, however there are a few that have 2 handles designed to be used by both hands. FeetFoot Ascenders are usually made to attach to a specific foot, left or right, or may be either/or. OtherMost other types tend to not have a preference for handling or are not made to be pulled on without additional carabiners, ladders or materials and are considered both left and right handed. |

Both / Either |

Features  FeaturesCertified PulleySome rope grab devices function as a weight certified pulley when hung from an anchor in a hauling situation. These pulleys ease efficiency and movement of the rope when under load but in order to be safely used to haul large weights and humans, these devices must pass extra certification (EN 12278/UIAA). Note: Not all devices with rolling surfaces/pulleys have been certified to be used as a pulley. Certified Pulleys should not be confused with Built-in Rollers which are not rated to hold weight. Integrated BelayThese ascenders have a built in single slot for passing the rope through which allows the ascender to be used as a belay device in a controlled descent on a single rope. While designed to allow a climber to transition from ascending to descending on the same rope, this feature can also be used to lower out a climber or load and could technically be used to belay in a pinch. Built-in RollerA built-in roller can be helpful when working at height or ascending a rope with a progress capture device. It can help to add efficiency and give mechanical advantage by redirecting the rope above the climber. This can also be helpful during hauling situations where continual dropping and lifting of a climber’s weight is necessary. These rollers are not rated as a piece of PPE and should not be confused with Certified Pulleys which are tested to hold a climber’s weight or heavier loads. Mid Attachment HoleA middle hole that a carabiner can fit through. This is particularly helpful for higher placement of a carabiner pulley setup. Works on WebbingSome ridged toothed ascenders are designed to be used on flat webbing as well as ropes. Their intent is not necessarily for vertically scaling webbing, but rather for clamping backups and positioning along webbing, which can be particularly useful during rescue and work at height situations. | Not applicable |

Rope Range  Rope RangeCertified DevicesAll ascenders and rope grab devices that have been certified by the EN or UIAA are required to list a rope range. This range is not a specification of the test, but rather the cert is an acknowledgement of the device functioning correctly with that size rope. Essentially, a manufacturer can seek to certify a device to work with any size of rope they want, and if it passes the certification at that size then they are required to print it on the device. The most common rope ranges tested for EN567 are in the 8-13mm range. The most common ranges for EN 12841A/B are 10-13mm. Non-certified DevicesDevices that carry no certification may or may not have specified rope ranges. Foot ascenders and other rope grabs that are not made to be used as PPE (Personal Protective Equipment) do not have a standard operating range of rope sizes and should be looked at more closely to determine the manufacturers recommendation for their use. Rope ranges for these devices can vary wildly but are often in the 10-13mm range. |

8 - 12mm EN 567 (as a rope clamp)

|

Certification  CertificationEN 567:2013 (UIAA 126)This is a static certification. It denotes a static holding power of 4kN and does NOT include testing the device to arrest a fall of any kind. EN 567 is described as a rope clamp device and is tested ONLY to be used to capture progress in one direction on a rope or webbing. EN 12841:2006This is a certification in three types: A, B & C. 12841:A (12841/A) is certified and tested to hold a static pull of up to 15kN AND a dynamic fall up to 6kN.

EN 12278:2017 (UIAA 127)This certification applies only to devices with pulleys. It certifies that the pulley itself rolls correctly under a load of 2kN and does not fail at or below a load of 15kN. UsesIn general, EN 567 can be thought of as progress capture and a safety backup in static situations, such as being trailed along a fixed line. When used for safety in a more dynamic situation like toprope soloing, they should always be used with backup devices which are certified to catch a dynamic load such as a device with the 12841:A certification. Devices that are 12841:B are more complicated. While they are tested to catch a dynamic load they are not tested to ensure that force doesn't exceed 6kN, which means they may lock in a way that transmits a greater amount of force from a fall to the anchor. Since their holding power is not tested beyond 3kN after this fall arrest, they should never be relied upon as the sole safety device to catch a fall. Devices with pulleys rated EN 12278 or UIAA are most often capture pulleys meant to be utilized as hauling devices. The certification denotes that they are safe for heavy loads like multiple humans and haulbags which are often much more than 100kg (220 pounds). If an ascender has a roller and does not have this cert, it has not been tested to hold this much weight so extreme caution should be used when utilizing it in this fashion. It is important to note that devices often have multiple certifications. For example a device may be tested to hold EN 567 forces AND be certified to pass the 12841:A standard. If purchasing any devices in the ascender category we highly recommend understanding ALL of your needs and the forces they can generate and being aware of a device's limitations before trusting your or someone else’s life to it. Note: We only include current standards. This means certifications like EN 567:1997 (year 1997 vs year 2013) are outdated and not included. |

CE EN 567 (holding 4kN) |

No reviews yet.

If you know of a good product video that should be here, let us know, and we'll put it up.

If you're looking for gear videos in general, check out our Vimeo and YouTube channels to see the newest gear.