Black Diamond Crampon Bag and Toolbox general information and instructional pictures.

Ultralight 16cm

Description

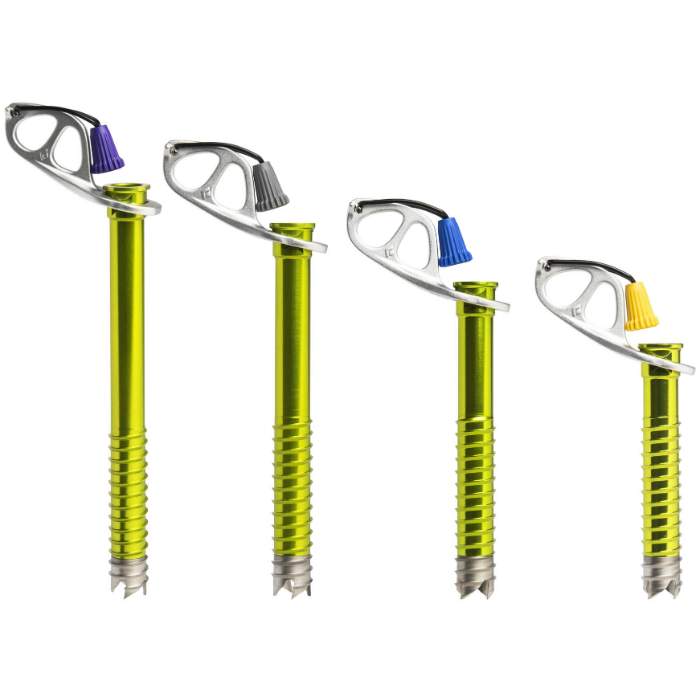

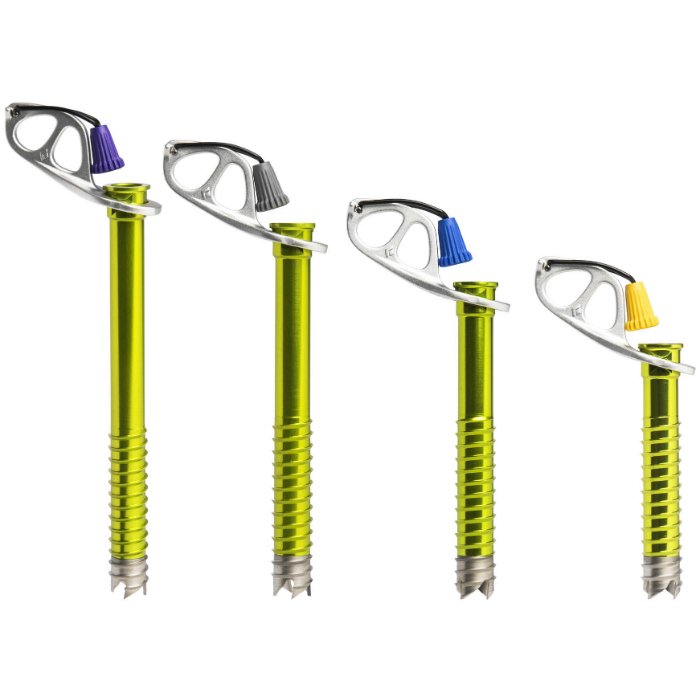

The lightest ice screw in the world, the new BD Ultralights are crucial for fast and light objectives in the mountains. Built for ski mountaineers, glacial travel, and gram-shaving alpinists, these screws feature an aluminum body with steel tip and an innovative wire-gate color-coded Express handles to differentiate length.

Designed for ski mountaineering, glacial travel and high-end alpinism, the Ultralight Ice Screw says it all in the name. Weighing in at 45% lighter than our Express Screws, the Utlralight Screw combines a steel tip with an aluminum body and forged aluminum hanger that features two clip-in points. The innovative wire-gate Express handle shaves more weight and also clicks open and closed. The Ultralights are also easily identified by length with the classic BD color scheme.

Retail price

When you click a link below and then checkout online, no matter what you buy (climbing gear or not), we get a small commission that helps us keep this site up-to-date. Thanks!

Weight (grams / ounces)  Weight (g / oz)In grams and ounces, the weight, as stated by the manufacturer / brand. | 81 g / 2.90 oz |

Length (cm)  Length (cm)Ice screws range between 6 - 30 cm. Generally speaking the sizes can be thought of as: Short - 13 cm and belowShort screws (“shorties” or “stubbies”) are for thin ice found on harder ice climbs and/or in crappy conditions. Medium - 14 - 17 cmWith ideal conditions climbers will be able to plug medium-sized screws with no problem. They have a nice weight to length balance. Long - 18 cm and aboveLong screws are most often used as anchors or in crappy ice conditions where they can go deep to find the real ice below. Mountaineers may also prefer long screws as they can gain better purchase in less than ideal ice and have less chance of melting out. How Many To CarryThere is no standard of how many screws to carry of each size. It will vary depending on where you’re climbing, your style of climbing and what level you’re climbing at. Some climbers will get a variety of the sizes, while others might get a majority of medium screws, a few shorties for thin spots and some long screws for anchors and bomber placements. Note: The amount of threading on each screw does not change even when the overall length changes (exception: e-climbs screws). |

16 cm |

Feature(s)  FeaturesNo Handle / KnobAbout 30% of the options

Pros: Cheaper Cons: No “speed” handle/knob for faster threading Note: This is not currently a feature to filter on (coming soon), but is important to see the difference. Handle (non-fold)About 24% of the options

Pros: There is an extra “handle” or “knob” for faster screw threading. Cheaper than folding versions. Cons: Some of the knobs stick out substantially and could cause the rope or draws to get caught on the lengthened handle. Handle (folding)Around 42% of the options

Pros: Foldable handle allows for quick threading and reduces snagging potential by folding out of the way. Cons: More expensive. Color CodingNearly 70% of the screws are color-coded, and this represents nearly all of the screws that have handles/knobs (color coding can also be on the hanger or the tube itself).

Pros: Like on cams, color-coding makes for faster size identification. Cons: Generally color coding only comes on more expensive screws (with handles) There are 7 brands that follow red, yellow, blue, gray, green as a small to large standard, but that is not consistent across the industry. Sewn Sling (Pre-Attached to the Hanger)

Pro: You don’t have to carry quickdraws, so it saves weight and speed of clipping. Con: The length of this sling may not be ideal and it is not adjustable 2 Clip Points on the Hanger

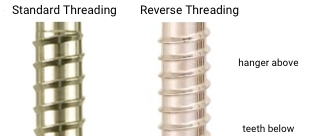

Pro: More clipping options, especially ones that are closer to the ice to reduce leverage in a fall situation. Con: This comes standard on only a few screws so your options are limited. On some configurations this will also make the hanger much larger. Reverse Threading

This is the most controversial feature. Grivel and CAMP (which make up 30% of the ice screw market) use reverse threading on all of their screws and claim that this angle is more effective at spreading an impact load across ice. If you are interested in the merits of the “reverse thread” design, click to see photos of the concrete tests (reverse threading pulls out more concrete than standard threading) and read about the concerns of testing in concrete. Read discussion of the engineering that goes into thread design and the questioning of straight pulls while testing to judge if reverse threading would make a [significant] difference in the event of a fall on ice. |

Folding Handle Color Coding 2 Clip Points |

Strength (kn)  Strength (kN)In kilonewtons, the strength as stated by the manufacturer / brand. |

10 kN |

Materials  MaterialsHangerThe material of the ice screw hanger (what you'd be clipping a carabiner into). Expect Stainless steel or aluminum here. TubeThe material of the tube of the ice screw (aka shaft). Most often it'll be Chromoly or steel but Grivel, Petzl and e-climb (and perhaps others) offer an aluminum tube ice screw option. Nearly 90% of ice screws are made from steel because steel is stronger and more durable. Aluminum screws will dull and wear out much faster and are not designed for crag-style ice climbing. They are specialty ice screws best used for fast and light ascents. TeethThe material of the teeth. Most often the tube material and the teeth material will be the same (e-climb and Petzl are exceptions). Often, screws with aluminum tubes will have steel teeth to help with durability. | Hanger: Forged Aluminum Tube: Aluminum Teeth: Stainless Steel |

Certification  CertificationsThe main climbing gear certifications are CE and UIAA--and normally the UIAA creates the rules that the CE body also supports. When possible, we try to list all the certifications the product carries. To sell a climbing product in Europe, the device must be CE certified. There are no official requirements to sell climbing gear in the US. The UIAA certification is a voluntary process. Ice screws are not certifiable below 10cm. Learn MoreRock and Ice Certifications Guide |

|

No reviews yet.

Lightweight and functional screws that really bites into ice making placements quick and easy, definitely my new go-to screw. However, like the Petzl aluminum screws they bind in green or wet ice so it’s still a good idea to have a few steel screws on the harness.

“Have I gotten better or is it the gear?”—this haunted me as I deftly placed the new BD Ultralights (13-, 16-, 19-, and 22-cm lengths; 2.6–3.4 oz) on the steep lines above Vermont’s Lake Willoughby. With instant bite, smooth boring, and easy-action handles, there was no need to run it out. Aggressive geometry on the steel teeth gave a bulldog bite, and the aluminum shaft—an ample 2cm in diameter—provided a smooth, stable drive. Add in a snappy, fold-out plastic handle, and these things practically spin themselves in. Meanwhile, dual clipping points provided greater versatility during anchor management. Pairing aluminum and steel, BD has shaved 45 percent off the weight.

The weight savings come from the construction: the screw’s body is made of a green-tinted, forged aluminum, while the tip is stainless steel. The tip is essentially a sleeve that overlaps with aluminum body by about a centimeter. So feel free to bring an extra couple of stubbies or one long V-thread-specific screw without worrying that you’re packing on the gear pounds.

Black Diamond designed the Ultralights to fill a specific niche—mainly ski mountaineering, glacial travel, and big alpine adventures. For these pursuits, where weight savings can be critical, the Ultralights are clearly the new gold standard, and I would rate them 5 stars. However, after several days of climbing frozen waterfalls using both Ultralights and traditional Express screws, I noticed some design limitations that, in my opinion, were not offset by the reduced weight when used exclusively for this application. Therefore, these screws will prove ideal for specific audiences and applications, but do not look to the Ultralights to become the new workhorse screw at your local ice crag.

This video, put out by Black Diamond, demonstrates how to properly sharpen your ice screws. Note: You may want to mute your speakers before watching this video, as there's no voice and the music may be unappealing to sensitive ears.

A pictoral representation of the UIAA-151 and EN-568 standards for ice screws.